Packaging is more crucial than ever before. Why is this? Due to the trend toward online shopping, the entire globe is experiencing it.

We’ve all experienced how easy it is to view something on our smartphones. Click on it, visit an online store and place an order for it. In some instances If we place our order earlier in the morning, the product will be delivered to our doorstep before nightfall.

Same-day delivery is pretty popular in countries of East Asia.

With goods of all sorts being delivered and shipped on an everyday basis, there’s a sector that is growing as never before. We’re talking about the industry of packaging.

THE PACKAGING INDUSTRY

Between 2018 and 2028, the global market for packaging is expected to grow by nearly 3percent per year to more than $1.2 trillion.

The market for Boxed Packaged Goods is expected to continue growing because consumers are buying more online, which will increase demand for certain kinds of packaging and products.

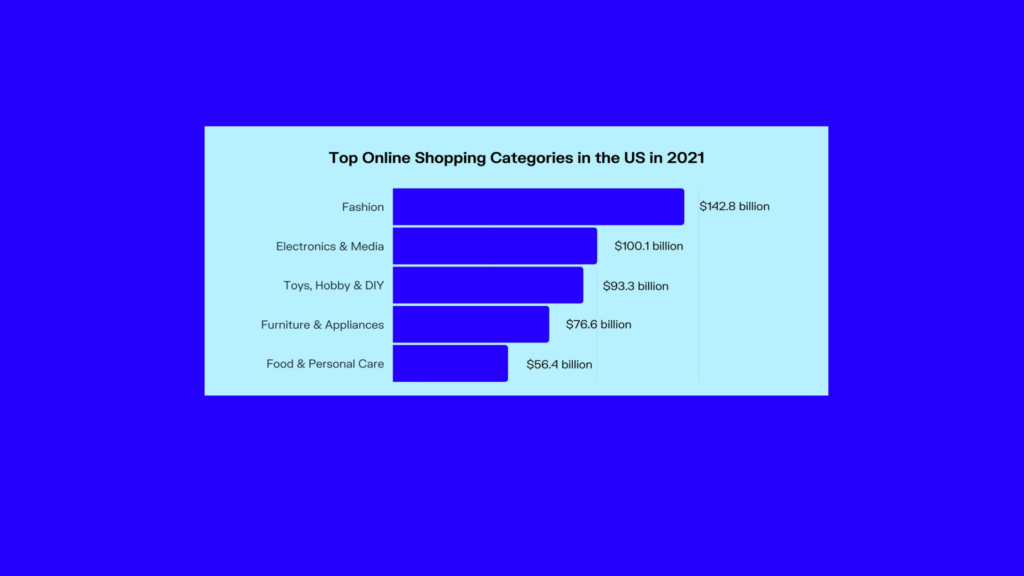

Which are some of the items customers are buying most often on the internet?

Top 5 Products Ordered Online

- Clothing

- Books, movies, music & games

- Shoes

- Consumer Electronics

- Alcohol and foods

Many questions on boxes. On top of that, you need to ensure that the packaging is cost-effective. The packaging and shipping boxes are more secure than standard packaging, as long-distance transportation is becoming more commonplace, and keep in mind that retail packaging plays an important aspect in providing a positive customer experience.

We realized that the most efficient method to tackle this packaging dilemma is to take an examination of packing materials, packaging materials packaging boxes, or packaging materials, whatever you would like to refer to each one individually.

We’ll let you know which packing materials are better suited to electronics or should be utilized for food packaging or storage boxes, an outside boxes, or customer directly contact boxes.

DIFFERENT PACKAGING MATERIALS FOR PACKAGING

CORRUGATED BOXES

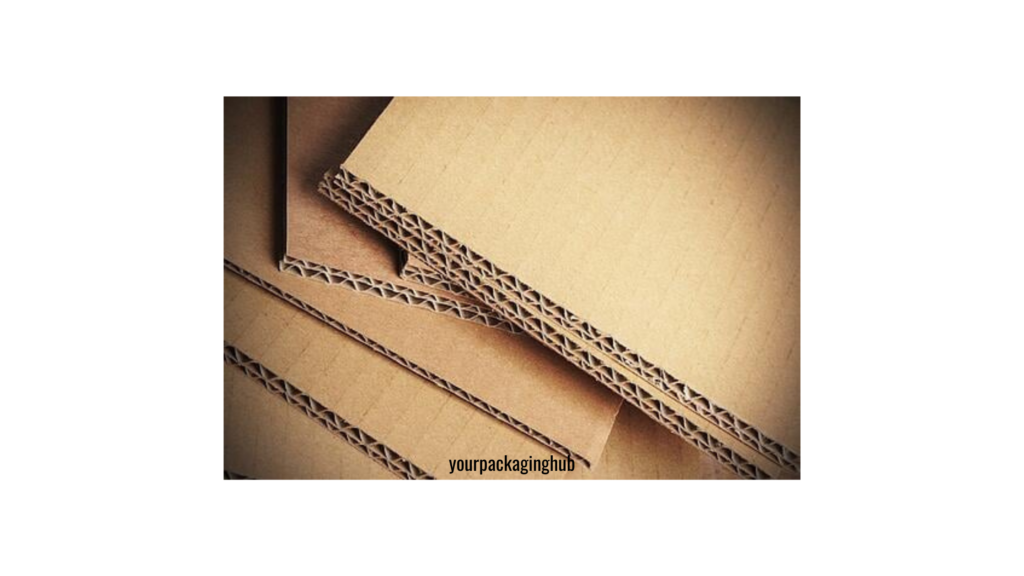

A corrugated boxed packaged goods differ from cardboard boxes.

Corrugated refers to corrugated material Three layers comprise the corrugated board. They are three thick sheets of paperboard.

The two sheets that are on the outside are flat, and that in the middle is an irregular shape. Check out the picture above.

The three layers are joined to each other using a starchy and thick glue that is very common in the industry of packaging.

The pieces are joined to create a corrugated container.

Corrugated boxes Benefits as well as Applications

- They’re ideal to ship all sorts of items, from Boxed Packaged Goods to Food Boxes.

- The multilayer structure ensures that the products are safe during transport and handling. It also makes great exterior packaging.

- It offers moisture protection

- They’re simple to modify and are suitable to display boxes in certain settings.

- They’re inexpensive and made from light material

- Boards made of corrugated are simple to recycle

Corrugated Boxes Drawbacks

- They don’t support a premium style.

CARDBOARD BOXES

This refers to any box that is made of thick paper pulp. The material used in greeting cards is also cardboard.

The cardboard boxes are very lightweight and flexible packaging containers.

They are usually made up of a single layer, and are packed flat in order to conserve space. They are then assembled by pressing the flaps, or folding panels. they are referred to as folding cartons.

Cardboard Box benefits and Applications

- Highly flexible packaging boxes

- It is easy to create boxes custom to your specifications in all kinds of sizes and shapes.

- Very little weight

- Packaging design that is flexible, you can print whatever you’d like onto it.

- High-end finish to provide the highest customer satisfaction and the best the best packaging for retail.

- It is ideal for packaging all sorts of goods, from food to electronics ;it increases shelf time.

- Highly recyclable

Cardboard Box Drawbacks

- It may prove to be an unsuitable packaging option for heavy objects

- When it is stacked, based on the box’s weight, it could change shape

- When exposed to water, it will deform easily.

CHIPBOARD PACKAGING

Chipboard is a durable, lightweight cardboard-like material which can be used to pack boxes for various products. It is available in a variety of wall thicknesses ranging from 10 points. to a maximum of 100 points.

Of all the packaging options this one is the least durable, making it better suited to display, retail and POP purposes.

Common uses of chipboards are

- Toothpaste packaging

- Medicine packaging

- Perfume packaging

Advantages of Chipboards, as well as Applications

- Cost-effective and affordable

- It can be utilized to serve a variety of packaging needs including medical packaging, food packaging food items.

- Printing is easy on HTML0.

- Extremely lightweight

- These boxes for packaging are extremely recyclable

- Direct printing , chipboard provides an excellent whiteboard surface for artwork. This allows images as well as high-quality images to be printed right on the spot.

Chipboard Drawbacks

- Chipboard isn’t intended to be used for shipping applications.

- These kinds of boxes for packaging aren’t waterproof at all.

RIGID BOXES

These boxes are constructed from extremely condensed paperboard which is four times thicker than the typical folded carton.

The boxes feature a lovely high-end and glossy finish that allows printing. it’s perfect for products that are high-end, like boxed packaged goods.

When you purchase packaging like this, you should be aware that you cannot deliver products using just this type of packaging. You require at least one additional box.

Rigid Box Advantages as well as Benefits

- It comes with an exquisite design and feel that’s perfect for top-of-the-line electronic devices

- They’re easy to modify

- This type of packaging is not collapsible.

- It is feasible to convert this container biodegradable

Rigid Box Drawback

- Expensive

- These boxes form part of the user experience So they should be secured by an outer box.

FOIL SEALED BAGS

Foil sealed bags are superior to plastic bags and paper bags. They’re used to package small objects, with of which the most frequent are food items, but these kinds of bags are also suitable for packaging products for boxed packaged goods as long as they’re antistatic.

Foil Sealable bags made of foil Benefits as well as Benefits

- has anti-static properties and soft

- Thickness may be altered easily

- It is widely used for electronic products like printed circuit board , electronics components like hard disks or

- as an outer packing will not only save money but also shield electronic devices from damage caused by static generated through friction between insulators

- This bag with anti-static properties is the most effective packaging substance for electronic parts PCB, which allows static escape from PCB and prevent the risk of

- It is additionally possible to print the that have branding.

- It is completely vacuum-sealed from the outside world It provides complete protection against dust, moisture and any other cause of contamination.

Sealing of Foil Bags Drawbacks

- They’re not recyclable.

- It is not able to be used to create separate packaging. At the very least, two cardboard boxes will be required.

- This packaging does not ensure that you are safe from crushing or dropping

PACKING PEANUTS

The packaging material is used in boxes to provide additional protection between product and packaging, they’re constructed of Styrofoam and, aside from the peanut-like shape that you can notice in the above image, Styrofoam can be molded into various shapes that can be adapted to the edges of a product.

When removing boxes of large electronic gadgets like T.V.s refrigerators, TVs and ACs, it is typical to see Styrofoam in various shapes, providing additional shielding between the boxes and devices.

Packaging Peanuts benefits and Applications

- They’re affordable and great to protect boxed packaged goods that are large during transporting

- Drawing Peanuts Packing Drawbacks

- If they’re made of Styrofoam they’re not recyclable.

5 Tips For Choosing Elegant Box Packaging for your Product

BOXED PACKAGED GOODS – NATURAL MATERIALS

The majority of packaging we see today is not recyclable or recyclable in any way or even if recyclable, they don’t make it to recycling facilities.

Numerous Boxed Packaged Goods of every type including a small juice box to a massive shipping container, end up in the garbage; in which months pass until they begin to decay and, before that happens, they may make it into rivers and oceans, possibly causing harm to wildlife.

Styrofoam is a material that takes around 50 years to degrade.

There is no reason not for human beings to begin looking for ways of packaging that is not just biodegradable, but also recyclable. it’s also an essential element of sustainability for the packaging industry of packaging.

Imagine the possibility that packaging materials could be put out in your front or back yard and decompose within just a few days, and provide nutrients to the soil.

Companies are currently working on this type of packaging boxes and materials.

Let’s look at a few possibilities.

MUSHROOM MYCELIUM + HEMP – PACKAGING MATERIAL

There’s a packaging company striving to make use of this biodegradable, biodegradable material as the next method to package products.

In their own words.

Mushroom(r) The packaging is made of two ingredients: hemp hurds as well as mycelium.

A highly efficient packaging solution that is cost-effective thermally insulating, as well as water-resistant.

Add it to the soil for composting within the next 45 days.

GREEN CELL FOAM – PACKAGING MATERIAL

Another option for packaging that is sustainable. This material is utilized as a protection element for beverages, food items and electronic devices.

Listen to this:

Green Cell Foam is NOT recyclable.

Instead of taking up space in your garage, home or other recyclable containers, we recommend washing this packaging material into the sewer either composting it, or using it as a fuel starter for fireplaces, grills or firepits.

Or, you could toss it away knowing that it will return to earth, safe.

The information is from their website. Isn’t it an excellent package choice

GEAMI – PACKAGING MATERIAL

We’ve all opened packages that contained bubble wrap. While it’s enjoyable to play around with it for a bit it’s important to remember that it is plastic. Many boxes are bubble wrapped plastic and the interior is filled with bubble wrap too.

This isn’t the situation for any longer.

Geami is a recyclable and recyclable blend of kraft and tissue and, when combined using the manual wrapPack converter can wrap a product quickly without the requirement of tape.

In case your company is dedicated to conserving the environment, be sure your containers are clear of any plastic is possible.

MOLDED PULP – PACKAGE BOX

It is sometimes referred to by the name of egg packing. The only components needed for the production of moldable pulp are recycled papers and water.

It’s an excellent biodegradable packaging box.

It is biodegradable since it is made from wood and other plants that are sustainable when exposed to humidity, heat or oxygen as well as rain the material rapidly degrades.

In recent years, the manufacturing process has been improved, so the final products are smoother surfaces and more refined look and feel.

With its improved appearance the pulp packaging is being utilized for a broad array of applications as well as traditional packaging for protection (end caps and egg cartons).

Take a look at this complete molded pulp box designed for electronic devices.

The types of packaging that we have mentioned in this section are natural, biodegradable and eco-friendly They all function in a manner or another to safeguard packaging that contains electronics or an element of the package itself.

TRANSIT PACKAGING

The final part in the process of packaging refers to the type of container utilized to transport goods from one point to B, often across multiple points.

The more robust, the better, but remember that it must be efficient for your operation.

The various types of transport packaging called moving boxes or outer cartons transport outers or any other type typically made from corrugated board and cardboard. They are made to ensure that the goods get to the person receiving them without damage.

The structure of transit packaging is mostly determined by the need to protect the product but is also influenced by dimension and the efficiency of logistics.

For the majority of consumers, the product’s branding and packaging are one unit and that is the reason why transport packaging should not be overlooked.

WHAT ARE THE PACKAGING TYPES?

Primary packaging

The primary packaging that was used to protect the product.

The packaging that houses the product and helps keep the product in good condition for a long time. It could be a paperboard carton, glass container or aluminum pouch or a bottle made of plastic.

Primary boxes (bottles or bags as well) cannot be held accountable for handling rough and are covered by the secondary packaging.

Sometimes the packaging that is primary will be entirely removed, such as in a smartphone. However, other times, it is intact, such as the wine bottle, which is a wine bottle.

SECONDARY PACKAGING

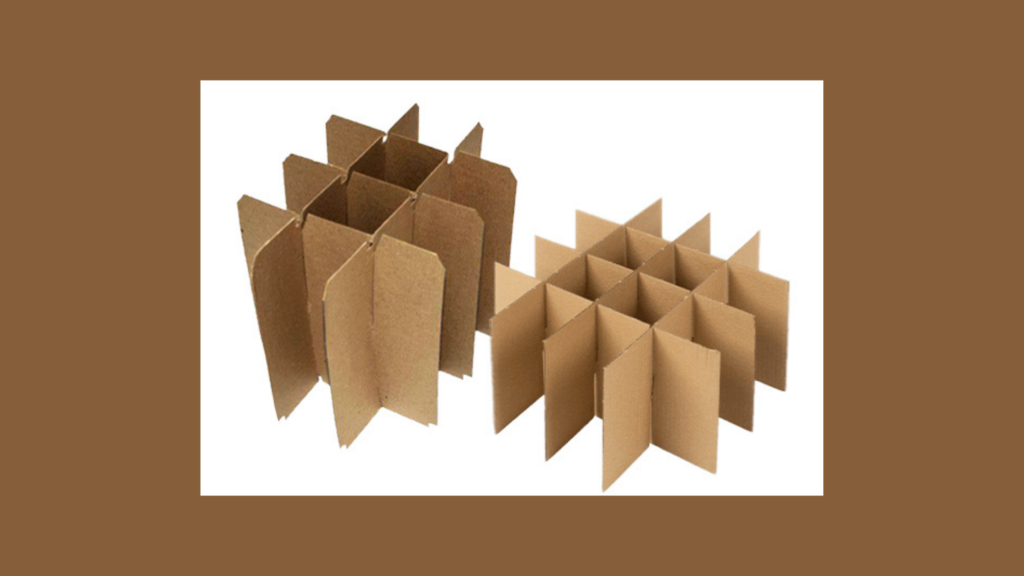

This is the box that holds the various units.

This kind of package, like the thick three-layer boxes, can be used to move the product from A to B.

They could be the cardboard boxes that are used to transport goods out of the store to the store.

It also contains the tape as well as the void fill material which was used to transport an item to a store or distribution center.

The packaging is not sent to the home of the consumer and tends to be removed almost immediately at the point of sale.

TERTIARY PACKAGING

This packaging serves to protect Boxed Packaged Goods used for secondary purposes.

The most popular sort of secondary packaging is corrugated brown cardboard.

The packaging is done at the warehouse prior to shipping the products.

The product packed is placed in cardboard corrugated boxes or a box made of wood. The additional packaging protects the product from rough transportation and also water damages.

Little More About Boxed Packaged Goods

Let’s explore various types of packaging options that you can make use of to improve your product and customer experience!

1. Paperboard boxes

Paperboard is a type of material that is light but robust. It is easily cut and modified to make custom designs and shapes. This makes it an ideal material for use in custom packaging. It is created by converting fibrous materials that originate from wood or recycled paper scraps into a pulp and after that, bleaching it. Paperboard packaging comes in different grades, each suited to different requirements for packaging.

Create a captivating and mesmerizing kraft packaging for your products

The SBS (or the solid bleached sulfurate) paperboard is suitable to package medicines, cosmetics like juice and milk cosmetics, frozen food items, and much more. Choosing kraft, or CUK (coated unbleached kraft) paperboard packaging are for those who prefer the natural and environmentally-friendly look of recycled paper, which can be used for similar packaging applications. It is generally believed to be less water-resistant, making it not suitable for food-related items, or packaging for frozen goods. If you choose the right combination of design options, the paperboard packaging can be stylish, but without the high-end prices.

2. Corrugated boxes

Corrugated boxes refer to what’s known as cardboard. These boxes are what you might think of as “cardboard since they produce bulky shoe, shipping, and storage boxes. Many people don’t realize is that corrugated containers also are available in various types based on the strength and durability that the boxes. Finding a specific corrugated product, however, is not difficult. How can you identify the substance? It is through the corrugated material (also called fluting). Finding a corrugated material is simple. It is composed of three layers of paper: one outside liner an interior liner, and a medium that is corrugated (also called fluting). Corrugated medium gives it rigidity and strength.

The primary source of material utilized to create the corrugated board is recycled paper. It is produced on huge high-precision equipment called corrugators. These kinds of boards can be reused and recycled again as a source for pulp fiber. Corrugated boards can be found in different kinds, including single faced, double-faced (single wall) twin wall, or triple wall. They are utilized to make packaging with distinct characteristics, performance and strength. It is then cut, then folded into various dimensions and shapes to create corrugated packaging. Other uses for corrugated board packaging are pizza delivery boxes small consumer goods packaging and more.

3. Plastic boxes made of plastic

Plastic is utilized in a myriad of items, including spaceships, paper clips, and even spaceships. Many of the traditional materials, including leather, wood glass, ceramic and many more have been replaced with plastic.

The packaging of plastic boxes has numerous advantages. They can be reused and are generally far more durable than cardboard boxes. Plastic containers that are airtight can aid in preserving the freshness of food and also eliminate contamination concerns. Plastic packaging is also resistant to breaking easily and is able to be kept in food storage under extreme conditions.

Another reason that plastic is a preferred choice for packing materials is due to its ability to show the product at any angle without having to open the packaging. It’s also flexible, light in weight and can be coated with coatings or films to enhance the look of the packaging.

Contrary to what many believe, the truth is that plastic is recyclable in that it requires less energy to create new plastic in comparison to glass and various other materials. The best part is that it’s very economical!

4. Rigid boxes

You’ve probably thought about what kind of box is utilized to pack iPhones or the high-end retail products like Rolex, Tiffany & Co and Marc Jacobs. You can tell it’s made of cardboard but weren’t certain because of its toughness and elegant appearance. This kind of cardboard is referred to as an unreinforced box.

Read More: Boxed Packaged Goods

An unibody box constructed from a highly compressed paperboard, which is four times heavier than the paperboard employed in the making of the standard folding carton. The most obvious examples of rigid boxes are the ones that are used to store iPhones and iPads from Apple. iPhones and iPads. They are two piece rigid boxes.

In comparison to corrugated and paperboard boxes, rigid boxes are one of the most costly boxes. They typically don’t require expensive dies or heavy machinery and are usually made by hand. The fact that they are not collapsible also makes the boxes a greater volume of shipping, which often results in more shipping costs.

These boxes are often utilized in merchandising cosmetics technology, jewelry, and the most luxurious of luxury. It is simple to include elements like lids, windows, platforms as well as hinges, compartments embossing, and domes into rigid boxes.

5. Chipboard packaging

Chipboard packaging can be found in industries like the medical, electronic and food industries, as well as cosmetics, food and beverages. Packaging Chipboard is basically the type of paperboard which is made from recycled paper stock. It is easily cut, folded and then shaped. It’s an affordable packing solution for your items.

It is available in a variety of densities, and its durability is determined by the extent to which its density is. If you wish images printed directly on the chipboard treat the chipboard using bleach sulfate, as well as CCNB (Clay Coated News Back) which will make the material more robust.

Chipboard is not suitable for your business that deals with bulky items, as it is a light material, used to make numerous grocery items, including crackers, cereal, boxes, and more. In addition, if the storage space is laden and moist, the chipboard may easily deteriorate, resulting in expansion and discoloration.

6. Poly bags made of poly

The polybag sometimes referred to as a pouch or polybag made from a flexible, thin plastic film. It is among the most commonly used types of packaging and is able to carry various items such as food items, flowers and waste, chemicals, magazines, and more.

Polybags are tough, yet light, flexible and reusable. Because they are relatively simple to construct they can be completely customizable in terms of design, style and dimensions, but remain economical. Recycling plastic is also feasible using poly bags, based on the design. A majority of poly bags have security features including hanging holes, tape attachments and handles for carrying. These features ensure that the items are safe and appealing to the consumer.

7. Foil bags that are sealed

Foil sealed bags are commonly found in tea and coffee packaging. Why Is that? It helps keep Boxed Packaged Goods solid to keep the taste, shields it from the influx of bacteria and also helps extend the shelf longevity. Alongside food items foil bags, foil-sealed bags can also be used to pack bedding and clothing items. The process involves taking out oxygen in the bags in order to keep the fabric in place and secure to stop an increase in fungi as well as other bacteria. Nuts, cereals and cheese, smoked fish as well as cured and preserved meats are packed in foil-sealed bags to keep them from spoilage.